Dilution Plants

The IKA DPV dilution plant is suitable for all those applications where

two or more liquids are to be quantity-based and homogeneously mixed by

using a one pass operation. The continuous process enables a highly

efficient and economical production

The core of the plant is a single-stage inline dispersing unit

ULTRA-TURRAX®, which is sufficient for the most standard applications.

When it comes to higher demands concerning dispersing quality, the

homogenizer can be replaced by a three-stage machine DISPAX-REACTOR® or a

colloid mill type MK.

The ingredients are metered with a high accuracy into the dispersing

unit by means of pumps that feature very stable characteristics. Various

sensors and an electric control with optional upgrades for the process

automation round out the entire unit. All devices of the plant are

arranged on a common base frame as a compact skid with full piping and

internal electrical wiring. The plant is tested for operation before

delivery and the requirements for the installation on site are herewith

minimized. After connecting the feed lines and utilities, the plant is

ready for operation.

The distinctive feature of the IKA dilution plant is the optimal

procedure of the dispersing process. The phases to be mixed don’t come

in contact with each other until right before the dispersing tool. This

entirely prevents unwanted reactions such as lump formation.

The main application of the standard IKA dilution plant type DPV is the

thinning of 70% lauryl ether sulphate (LES) down to a concentration of

approx. 28% during the production of liquid detergents. Due to the

delivery of concentrated LES and on-site dilution, transportation costs

are greatly reduced so that a DPV plant is amortized in a short period

of time. In addition, the unit provides high flexibility in the

adjustment of the concentration as well as for the formulation of

multiple ingredient mixtures. Whether it’s utilized for the production

of household dish liquid or of skin care products, the DPV plant has

proven itself many times over.

Depending on individual customer demands, the following options can be realized:

Manual or automatic control

Fully automatic starting and stopping sequence

Measurement and regulation of the single flow rates

Recipe management

Receiver tank for ingredients

Additive dosing

The IKA dilution plant offers the following advantages:

Considerable time saving due to the production of the mixture in one passage

Homogeneous and fully lump-free results as well as constant dispersing quality

No foam formation: The fully closed system excludes the intrusion of air into the mixture

Extremely low space requirements as large mixing and storage vessels are not necessary

High level of flexibility relating to the production quantities

The plant can also be effortlessly utilized when the starting materials possess strongly varying concentrations and viscosities

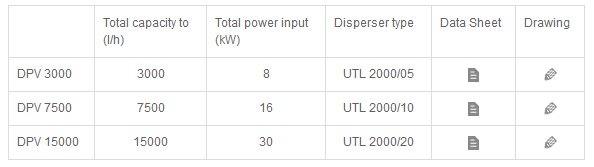

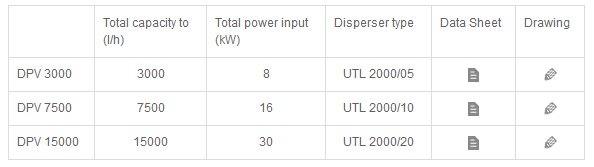

The technical data of the IKA dilution plant: